Post-pandemic landscape and challenges

New dynamics of global supply chains

Since the onset of the pandemic in 2020, global supply chains have faced challenges such as shipping delays, increased costs, and difficulty predicting demand. As of 2024, supply chains have become more complex due to geopolitical shifts, environmental volatility, and increased reliance on technology, and digitization, big data, AI, and machine learning have emerged as key strategies to overcome the challenges. We’ve looked at the key issues in the current supply chain and explored the major challenges in managing supply chains and effective strategies to address them.

1. Imbalanced supply and demand

During the pandemic, surging demand and shrinking supply led to inventory shortages and rising prices, and many companies struggled with meeting demand, production output, and managing inventory. After the pandemic, inflation followed, driving up the cost of raw materials and finished goods, while freight rates increased, leading to excess inventory and higher storage costs. In particular, incorrect demand forecasts for safety stock early in the pandemic led to a buildup of inventory, which has since returned to pre-pandemic levels, but it also caused wholesalers and retailers likewise, to prefer ordering in smaller quantities. This made it difficult to fulfill order requirements and led to higher unit costs in manufacturing. While inventory is piling up for certain products, some others are running out of stock, emphasizing the importance of accurate, data-driven demand forecasting.

2. Labor shortages and late deliveries

Labor shortages at every stage of the supply chain, from manufacturing to shipping, are a major contributor to lower productivity and higher costs. Labor shortages, especially in logistics and delivery, are cited as one of the major factors contributing to shipping delays. In the labor market, occupations such as truck drivers are struggling to fill positions due to an aging workforce and a lack of interest from younger generations.

This has accelerated investment in innovative technologies, including autonomous driving. The growing expectation is that technological advances will alleviate labor shortages and further improve the efficiency of supply chains. In fact, in a survey conducted by Ernst & Young, the majority of 200 supply chain industry executives said they expect a significant portion of their supply chain to be automated by 2035 as a result of increased investment in technology since 2023. This suggests that the role of technology in supply chain management is becoming increasingly important.

3. Bottlenecks caused by political instability and disjointed logistics systems

Inflation and rising international conflicts have had a major impact on supply chains in recent years, causing transportation costs to rise sharply. This year’s attacks on commercial vessels in the Red Sea have increased shipping costs globally and caused congestion on alternative routes.

These new geopolitical issues add significant toll on the supply chain re-balancing and recovery processes.

In addition, port facilities, rail networks, and road carriers in the supply chain tend to operate independently of each other, making it difficult to track and integrate shipments and lowering visibility into the supply chain. Better integration and cooperation between varying modes of transportation have become essential for efficient supply chain management and the elimination of bottlenecks.

4. Growing cybersecurity threats

Since the pandemic, advances in digital supply chain technology have greatly improved efficiency and speed. However, this digitization has also brought new challenges in the form of cybersecurity threats, or cyber attacks on the supply chain. As supply chain management becomes more reliant on informational technology, the risk of a critical data breach or cyber attack increases. According to a survey conducted by the Business Continuity Institute (BCI), nearly 56% of organizations cite cybersecurity as their top supply chain concern today, and small businesses are three times more likely to be targeted by cybercriminals.

What are supply chain cyber attacks?

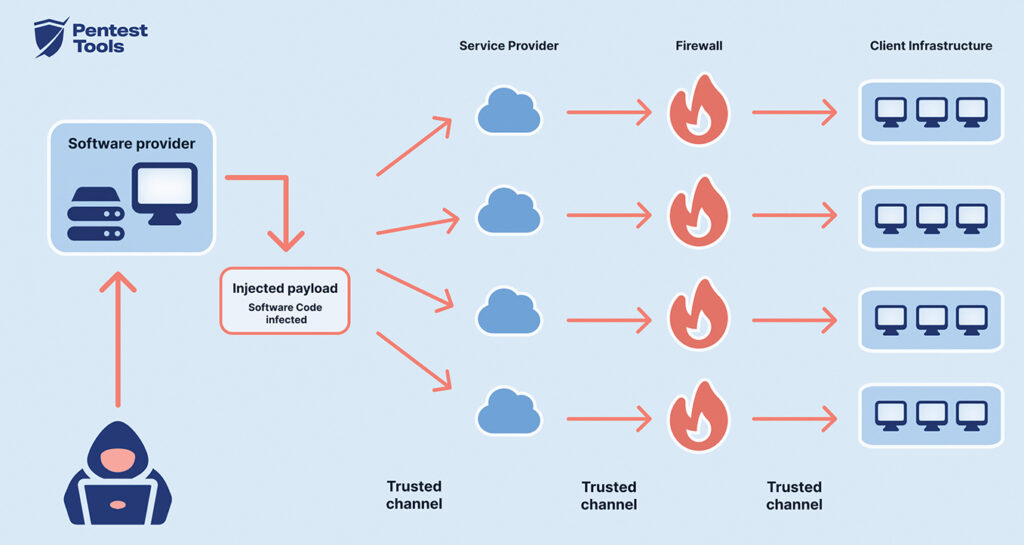

A cyber attack on the supply chain typically happens when a cybercriminal gains access to an organization’s network through a third party or the supply chain. Supply chains can be complex and extensive, making some attacks difficult to trace. Many companies work with dozens of suppliers, from materials and production equipment to outsourced work and technology. When a vendor’s software is compromised, it puts all companies that use it at risk.

Source: Pantest Tools

If a hacker installs malware on your software vendor, they can access your supply chain network through a trusted channel, your service provider, bypassing the firewall.

5. The ripple effect of regulatory change and trade policy

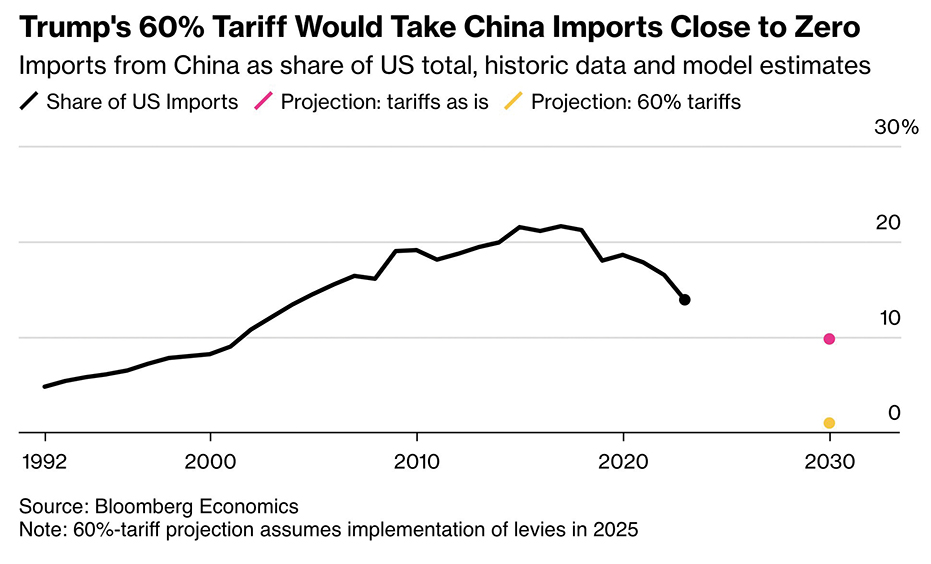

New customs regulations and changes in environmental and safety policies are among the factors that have a significant impact on the cost of international goods transportation and sourcing. Former President Donald Trump is considering tariff hikes as high as 60% flat on Chinese goods if he wins re-election this year, potentially escalating the U.S.-China trade conflict. In response, companies are reducing their reliance on China and diversifying their sourcing to Southeast Asia, Bangladesh, India, South America, and beyond. Some companies are also adopting the strategy of diverting products produced in China to Mexico and then importing them into the U.S. to avoid the higher tariffs associated with the U.S.-China trade conflict. This is an attempt to capitalize on the benefits of the North American Free Trade Agreement (NAFTA) and now the United States-Mexico-Canada Agreement (USMCA) to reduce costs.

Source: Bloomberg Economics

The chart shows that the share of Chinese goods in U.S. imports would fall to near zero if Trump’s 60% tariffs were implemented.

6. Climate change and increased environmental regulations

Climate change is having a serious impact on different levels of the supply chain, causing shortages of raw materials, product reliability issues, and changes in transportation routes. Last year’s drought in Panama, caused by extreme weather, resulted in increased costs and delays in transit times for many U.S. companies using the Panama Canal. In addition, cosmetics and chemical products can deteriorate or get damaged at high temperatures, so manufacturers are stepping up testing to ensure that their products are safe at extreme temperatures.

Source: euractiv.com

As regions in Southeast and South Asia, which account for a large share of hair and clothing production, become more vulnerable to heat waves and flooding, not only production activities but also working conditions are deteriorating, threatening workers’ health and jobs.

With growing societal concerns about environmental sustainability in addition to climate change impacts, companies are looking for more sustainable and eco-friendly ways to operate, which is leading to the adoption of environmentally conscious practices at each stage of the supply chain. According to the 2023 MHI Annual Industry Report, 48% of companies are feeling pressure to go green and adopt environmentally conscious practices, reflecting a global trend toward reducing carbon emissions, ethical sourcing, and increasing the use of alternative fuels for transportation.

‘New normal’ for global supply chains, calling for new strategies from businesses and retailers

- Diversify your supply chain: Prepare for unexpected demand by diversifying your sources rather than relying on a single vendor. This allows you to better respond to uncertainty through risk diversification.

- Investing in automation technology: Investments in AI and machine learning are on the rise, enabling more accurate demand forecasting and supply chain management. Investing in automation technology helps to increase work efficiency and alleviate labor shortages.

- Cost management: Look for ways to reduce costs to increase economic efficiency. This plays an important role in strengthening a company’s competitiveness in the long run.

- Training programs and employee education: Provide training programs to improve employees’ knowledge and skills and help them stay current with the latest technologies through required technical training.

- Enhance customer communication: Maintain a transparent channel of information and communication about supply chain activities to increase customer trust, notify customers immediately when goods are delayed, and offer possible alternatives.

- Diversify transportation modes and work with 3PLs: Utilize multiple modes of transportation and work with third-party logistics companies to address complex supply chain issues to address bottleneck issues and political instability.

- Monitoring regulatory changes and flexible sourcing strategies: In a rapidly evolving industry, keep a close eye on new policies and regulations and have a diverse sourcing strategy to reduce the risk of supply chain disruptions.

- Sustainable practices and green operations: Enhance the sustainability of your supply chain by adopting green transportation, using renewable energy sources, minimizing waste, and building partnerships with environmentally conscious suppliers.

- Strengthen cybersecurity: Invest in a robust cybersecurity framework to protect your company, your supply chain, and your customers’ information. Conduct regular security audits and employee training to counter cybersecurity threats and increase employee awareness.