Inventory management tips for 2023

Part 2 Maintaining optimal inventory level

Last holiday season, large US retailers launched unprecedented scale of sales events. Record high inventory level has triggered them to aggressively clear the inventory sacrificing profit margin. It tells you that large retailers are not immune from difficulty in inventory management. Failure in inventory management can be a fatal blow to a small business. Following the “Retail management tips: Part 1. Taking care of obsolete inventory” in the previous month, we cover how to determine an optimal inventory level for your business. Make your store lighter and your business profit heavier through efficient inventory management.

BY BNB MAGAZINE

What are the issues for inventory management in 2023?

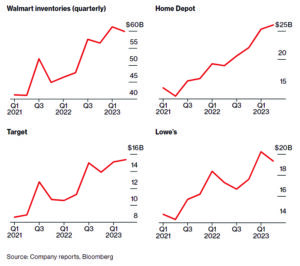

From 2021 through this year’s first quarter, major retailers in the U.S. displayed steep increases in inventory level as shown in the graph. Large retailers ran major clearance events because of the excessive level of inventory. After experiencing supply chain disruption during the pandemic, many companies increased inventory level but failed to sell as much as they expected. Did big sales events save the large retailers during the last holiday season?

US retailers inventory trend / Source: Bloomberg

The answer is “no”. Although Black Friday online sales set the record of $9.1 billion in revenue, the total U.S. spending in the annual shopping season, through November and December, went down. Consumers did not spend as much, and retail companies started the new year with the heavy load of last year’s inventory.

Beauty supply industry did not fare differently. A long-time manager of a large beauty supply store shared their experience of the hard economic situation in the year end. “Usually, the holiday season from Thanksgiving is the busiest of all, but last year, it was the slowest. Most stores probably generated half the previous year’s revenue.” When we threw a hardball by asking, “what’s your inventory management strategy for this tough time,” the manager wisely answered by saying, “now is the time when you don’t want any inventory. I would place an order for just the right amount.”

The key is how to determine “the right amount” to leave nothing unsold. Higher inventory level leads to reduced profitability, but back-orders can hurt customer loyalty. Determining the optimal inventory level that can generate revenue most efficiently will be the key for successful inventory management for this year.

Basics of inventory management that retail business owners should know

Inventory management is to control the quantity of goods by placing orders based on the market and sales trend. It involves not only demand forecasts but also optimal inventory level, safety inventory, lead time, order types, and so on. Although most retail business owners may find the technical terms unfamiliar, they may find that they are actually practicing the basics of inventory management in some way. Your street knowledge about inventory management is not so different from inventory management you can learn from books.

Optimal inventory level

Optimal inventory level refers to the ideal quantities of stock that you should have in a physical store and storage. Determining the optimal inventory level starts with setting the quantity you need to have for business and finding out when you need to reorder to replenish the inventory. Generally speaking, the optimal inventory level is the sum of cycle inventory and safety inventory.

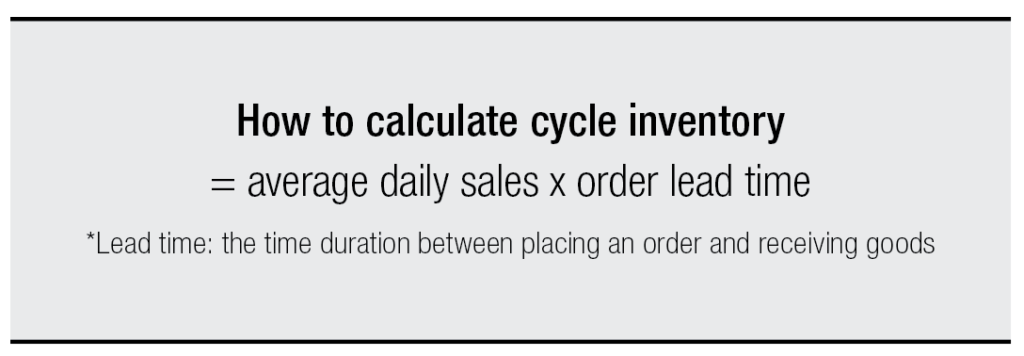

Cycle inventory is the amount that you expect to sell until next restocking, and it can temporarily go up and down according to the frequency of orders.

For example, you can sell five human hair wigs a day and your order lead time is 5 days. Your cycle inventory for human hair wigs is 25 (5 days worth inventory).

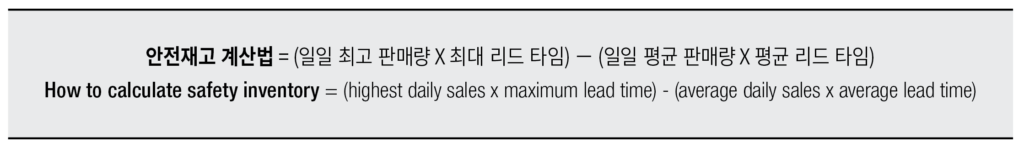

Safety inventory refers to the extra quantity you require to meet the extra demand or in case of an unexpected event. It is a reserve that you have in case of unforeseen events.

Let’s go back to the hypothetical situation above and say the delivery time for a given order can take up to 7 days, although averaging 5 days, from the date you place an order. If you have sold 10 human hair wigs in a really good day,

*Highest daily sales is 10, maximum lead time 7, average daily sales 5, and average lead time 5.

Therefore, safety inventory is (10 x 7) – (5 x 5) = 45.

This means, if you have 45 safety inventory, you will have enough inventory after selling out all of your cycle stock and place an order just then.

Although you can calculate the optimal inventory level by simply adding your cycle inventory and safety inventory, the reality is not that simply. Your optimal level of inventory fluctuates depending on the market and consumer demand shift. Hence, you will be regularly updating the figure. If you have a change of supplier (wholesaler), the lead time can also change, which will also make it necessary to revisit your optimal inventory level. Beauty supplies typically carry thousands of items at a given time. Can it be really possible to have an optimal inventory level for each item and update the lead time regularly? You may need to prioritize certain items.

The ABC analysis

When you study inventory management, you will definitely come across the ABC analysis. It analyzes past sales data traditionally, but many beauty supplies who carry a myriad of items still use the method. It makes sense to focus on important items if you have so many items, sizes, and styles.

The ABC analysis helps you to set priorities straight by dividing merchandise into three classes.

Class A: major items that contribute to 80% of your revenue, which require a high level of management

Class B: items that contribute to 15% of your revenue, which can move to Class A or B at a certain point, requiring a moderate level of management

Class C: items that contribute to 5% of your revenue. Minimal management.

A real world story – a retail store in Texas

“Beauty supplies carry beyond-imaginable numbers of items. Even considering the margin of error, you cannot possibly catalog all the items and regularly count them. As such, we only do inventory management for about ten items that contribute most to the revenue. I think that’s the best we can do.”

Order types

Maintaining the lowest inventory that meets the optimal inventory level is about “how often you replenish your inventory.” Order types come to play here. Order types can be divided into four categories based on two factors: “timing” and “quantity”.

Most beauty supplies place regular-varying quantity orders. In doing so, you set a day once a week or a month to place orders and forecast the sales volume for a week or a month to decide the quantity for the next order. Because you decide the quantity for each time you place an order, it will be varying in quantity.

The issue here is how to determine the quantity. You do not have accurate data or forecast model, so the procuring managers simply rely on their instinct or experience. To avoid such a gamble, you need to track and record received goods, order amounts, and sales amount continously.

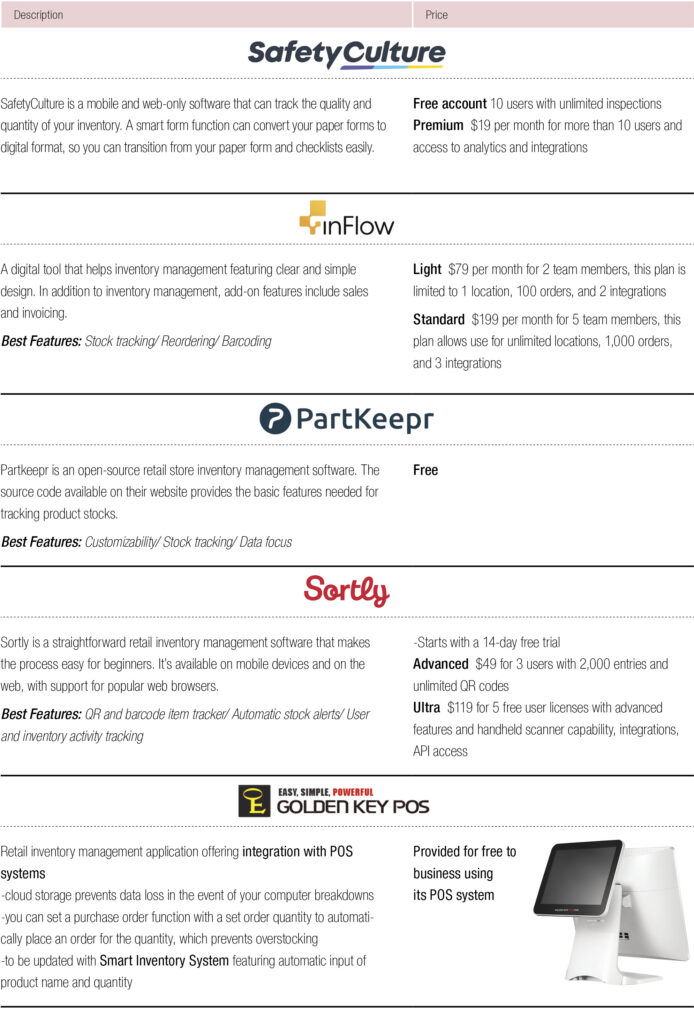

How to find the right inventory management tool

Chain stores that run multiple stores deploy inventory management software or have section managers who manage inventory via proprietary software. However, many small to mid-sized retail businesses cannot do the same thing because of the cost and lack of human resource. It might be great to use sophisticated software or a provider, but you can better benefit from tools that you can actually use. If you cannot get the hang of inventory management software, a handwritten list of inventory might serve you better.

©qad.com

Handwritten inventory list

Although it’s ancient, it is actually most commonly used. Anyone can write down the description of items and the quantity counted. It is easy to do and less costly.

If you go with a note and pen, you need to watch out for difficulties due to the possibility of errors, inefficiency, time consuming nature, and inconsistency in record.

Spreadsheet for inventory management

A few beauty supplies have their inventory using spreadsheet software such as Microsoft Excel. In these cases, those files contain simplified data such as item description, size, quantity and cost.

Spreadsheets are fairly commonly used for inventory management, so you can easily find templates on the internet. You can also find YouTube videos explaining how to use Excel to do inventory. Spreadsheets are time-saving than handwriting, but they have limits as to automation, are hard to track and correct errors, do not sync between mobile devices and desktops, and are vulnerable to damage or loss of the computer files.

Inventory management software

If you have purchased inventory management software, you should learn to utilize them 100%. Most applications offer free trials, so you should take advantage of them. If you have a POS system, the POS provider may offer inventory management tools for free or at a small fee and you can use it with your POS.

Key to the inventory management: high inventory turnover

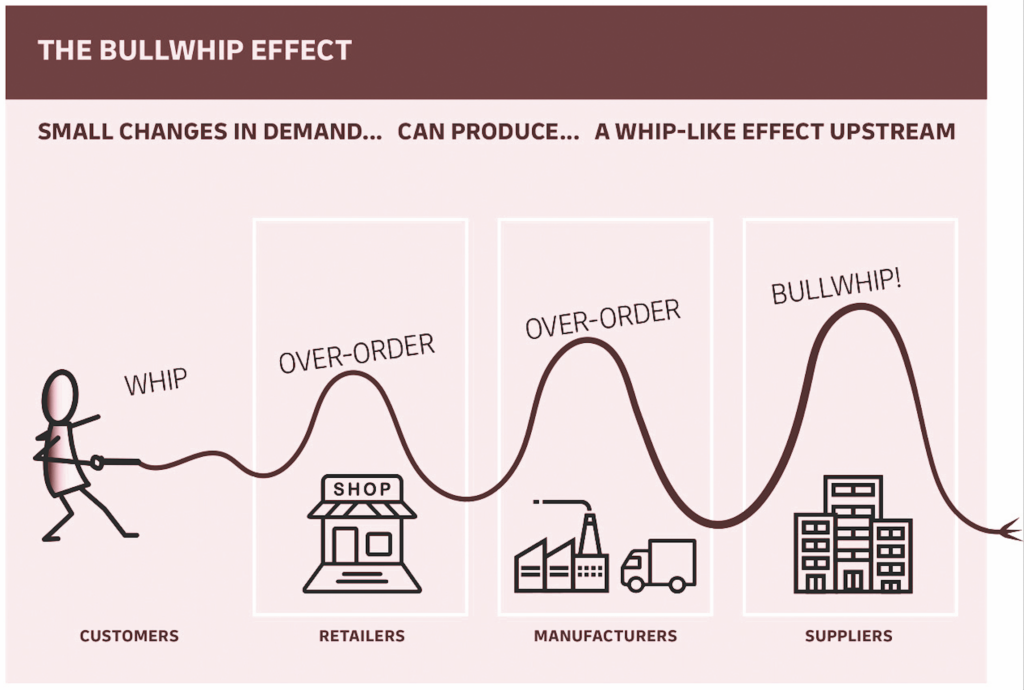

Even after you calculate the optimal level of inventory based on your inventory data, you might still fall for the human tendency to keep asking, “what if a customer looks for this? It’s better to have them just in case.” The phenomenon caused by anticipating higher volume of sales by retailers who place more orders, which eventually make wholesalers place more orders to suppliers, is called the bullwhip effect. In the end, actual consumer demand is only 10 but the manufacturers produce 40. Retailers, wholesalers, and manufacturers all like inventory levels to go up.

Bullwhip effect ©quora.com

Just looking around the retail stores, you will find the proof. From storage to restroom, they are filled with merchandise. A beauty supply store showed us 20-year-old wig products. A young beauty supply business owner who started early had various experiences in the beauty supply but was not an exception. In an interview, he confessed that obsolete inventory such as unsold seasonal products filled his storage although he had no expectation for them to sell. He thought about getting a warehouse because his business ran out of space, but he made a bold decision…

Inventory management is the biggest hurdle in the beauty supply business, according to him. As he tackled the hurdle earlier on, he would like to share tips for inventory management.

1. Regular inventory

– Once a week on the retail floor, inventory is performed, typically on Monday, while restocking items after a busy weekend. On Monday and Tuesday, he performs inventory and ordering, on Wednesday and Thursday, receiving goods and restocking, on Friday and Saturday, focusing on weekend business.

– Perform inventory on stored goods every two weeks. You only store goods in the storage when you order a large quantity of items to take advantage of bulk discount or to prepare for supply shortage in the future. You never store old inventory.

2. Seasonal inventory management

For seasonal items, you aim for November through January sales window and fully stock items by the end of October. You restock once after the Thanksgiving season, about in early-December, and you do not restock them afterwards even in the case of good sales. It will likely become an old stock or occupy your storage space over a year. Seasonal products are only for the show. It’s not to generate your revenue. March would be the end of product lifetime, so by mid-January, you cut the price to half.

3. Annual storage cleanup

Beauty supplies are infamously reluctant to discard merchandise. Products are money, they say. The problem is that the beauty industry is always welcoming new products that replace old products. If you have old inventory occupying your storage, you cannot bring in new ones. As such, to throw them away is actually to make money.

-Call the donation center first to at least claim tax deduction.

-Throw away everything without hesitation. Do annual cleanup of your storage.

Last year, he threw up merchandise that filled five industrial waste bins. Throwing away costs you, too. Still, to have a running beauty supply, you need to continuously refresh your inventory.

In a sense, “throwing away a lot is the best inventory management.” It might be the most important thing in inventory management.